When it comes to optimizing hauling performance, aluminum extrusions provide an efficient and cost-effective solution. Not only are they lighter than traditional steel parts, but they also offer superior strength and rigidity while requiring no additional maintenance or painting treatments.

As a result, using aluminum extrusions can lead to improved fuel efficiency due to decreased trailer weight as well as increased cargo capacity, faster acceleration and braking times, longer axle life expectancy, better maneuverability, and cornering capabilities, and quieter operation.

In addition to these benefits, the lower center of gravity caused by reducing mass further improves safety for both drivers and passengers alike.

With so many advantages to consider when looking for ways to optimize hauling performance solutions in truck trailers today, aluminum extrusion is an ideal choice that should not be overlooked.

The Impact of Aluminum Extrusions on Vehicle Weight and Fuel Efficiency

The use of aluminum extrusions in truck trailers has become increasingly popular due to its ability to significantly reduce the overall weight of the trailer and, as a result, improve fuel efficiency. In comparison to traditional steel-framed trailers, aluminum extrusions offer numerous benefits that can help optimize hauling performance.

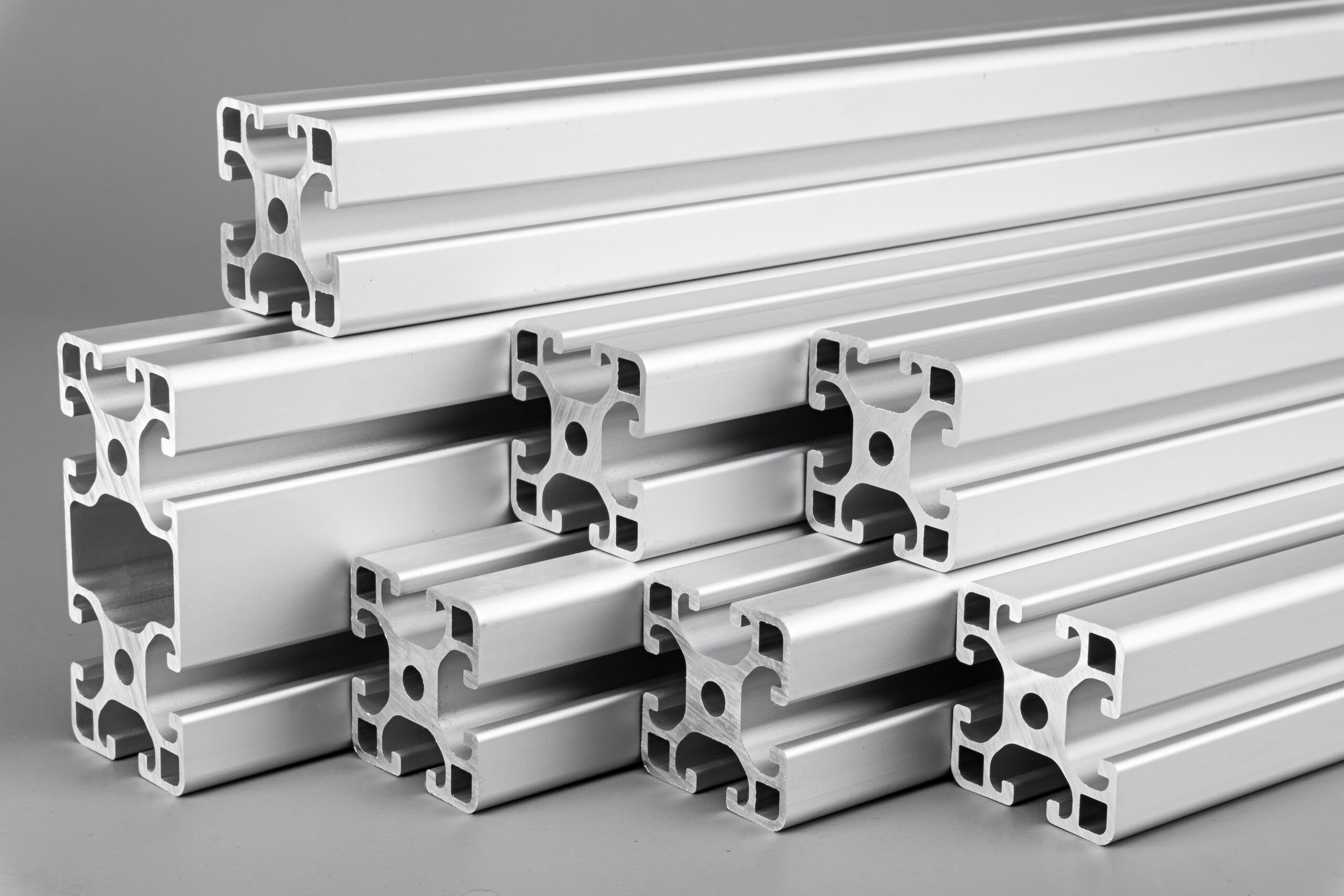

Aluminum extrusion is an efficient way to create lightweight frames for trailers while providing strength and rigidity. By substituting parts made from steel with those made from aluminum, it is possible to reduce overall trailer weight by up to 40%. This reduction in weight translates into improved fuel economy as lighter loads require less fuel consumption per mile traveled.

Additionally, since aluminum requires no painting or corrosion protection treatments like steel does, there are further savings on costs associated with maintenance and repair over time. Further benefits include increased cargo capacity due to decreased vehicle weight allowing for more maximum payloads; reduced vibration which increases interior comfort; faster acceleration and braking times; longer axle life expectancy; improved maneuverability; better cornering capabilities; quieter operation and improved safety due to a lower center of gravity caused by decreasing total mass.

In conclusion, using aluminum extrusions in truck trailers offers many advantages that can help improve hauling performance including significant reductions in vehicle weight leading directly to increased fuel efficiency as well as other cost-saving measures such as lower maintenance costs coupled with many additional benefits making them an ideal choice when considering optimizing hauling performance solutions.

Considering Design Variables When Utilizing Aluminum Extrusions in Truck Trailers

When considering design variables for utilizing aluminum extrusions in truck trailers, the first factor to take into account is the load capacity. Aluminum extrusions are incredibly strong and durable, making them suitable for safely carrying heavier loads than many other materials.

However, it’s important to ensure that any chosen extrusion has a sufficient load rating so that it can handle the weight of whatever is being transported without compromising its structural integrity or causing additional wear and tear on components like axles and brakes. The second design variable to consider when using aluminum extrusions in truck trailers is aerodynamics.

With streamlined shapes and profiles, these lightweight yet sturdy materials offer less wind resistance which helps improve fuel efficiency while reducing strain on engines caused by drag force.

By choosing an appropriate profile shape such as square-edged or round-cornered designs, trailer operators can minimize air turbulence around their vehicle both at speed and when stationary – a key factor when hauling over long distances where even minor improvements can make a significant difference across multiple trips taken over time.

Finally, selecting an extrusion with optimal corrosion protection should also be high on the list of priorities since this will protect against rusting from exposure to water vapor or road salt residue during transportation runs between destinations.

This ensures that parts not only remain safe but also retain their aesthetic appeal for extended periods of use without requiring frequent maintenance or replacement once they have been installed onto vehicles.

Cost-Benefit Analysis for Implementing Aluminum Extrusion

When it comes to optimizing hauling performance, aluminum extrusions are a great option. The cost-benefit analysis for implementing this technology is clear: the initial investment in extrusion materials and equipment can be offset by significant savings in fuel costs over time.

Additionally, aluminum extrusion may reduce wear and tear on truck trailers due to its lightweight properties, leading to fewer repairs or replacements. Finally, aluminum extrusions have been proven to increase efficiency in cargo transport as they offer a superior strength-to-weight ratio compared with traditional steel components.

All of these advantages make investing in aluminum extrusion an excellent choice when looking for ways to improve hauling performance.

Conclusion

Aluminum extrusions can be a great way to optimize the performance of truck trailers. 7075 aluminum extrusions are one of the most popular materials used due to their strength and lightweight properties, which makes them ideal for hauling heavier loads. As these extrusions become more widely available, companies should consider utilizing them to maximize their efficiency while keeping costs low.

The use of aluminum extrusion technology can help improve hauling performance in any type of truck trailer, ensuring that goods reach their destination safely and quickly.